Product Design - Product Prototypes - Mold Design

A-Z We Are Here to Help

Product Design - Product Prototypes - Mold Design

Product design, prototyping and mold design are optimized when integrated. Results are realized in cost effective tooling & production with high quality and consistency in parts. CORD Industries specializes in working with our customers from conception to consumer.

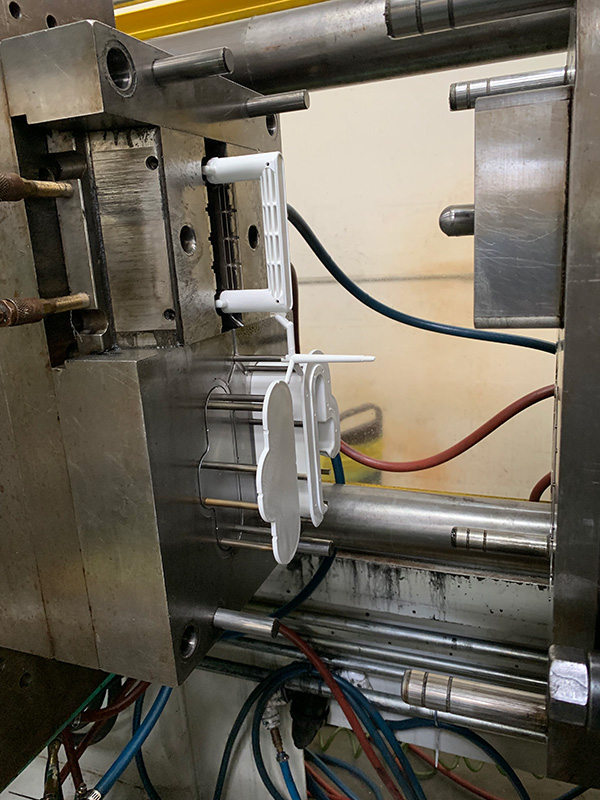

Injection Molding Design and Prototype support

If you’re looking for assistance in developing prototype ideas for a new product or revising an existing part, our talented and experienced team at Cord Industries is ready to get to work. We provide a range of rapid prototype variants that you can use to validate the function, form, and fit of the injection molding design you’re working on. The rapid prototyping approach is a particularly good solution for companies looking to get to market fast.

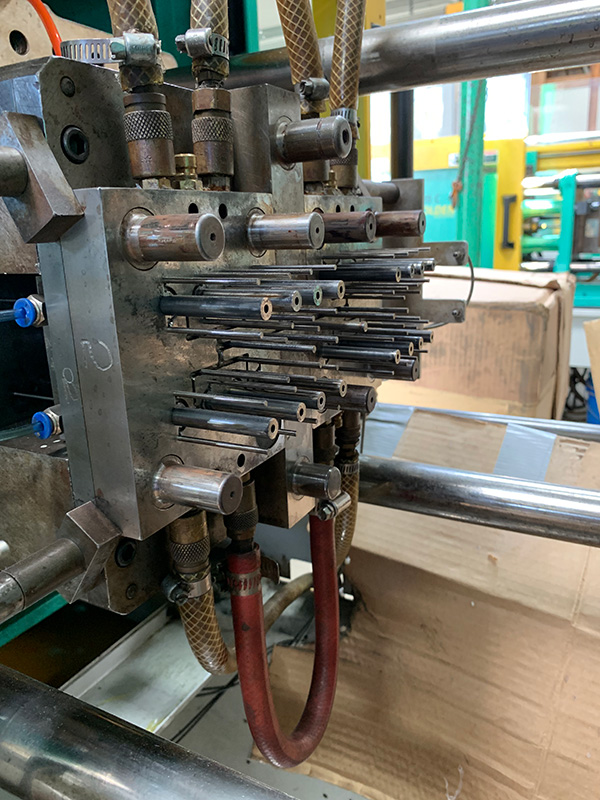

Injection Mold Design

One of the most important considerations when designing a mold is the final use and function of the part. Additionally, smooth production runs with capable molds aids in creating repeatable processes resulting in consistent high quality parts. Basic mold design criteria examines the shape and form of the part, type of material(s) to be used along with:

• The final function of the part

• How the part interacts with connected/adjacent items in the assembly

• The stresses applied to the part when in use

• How the material interacts with the mold during the forming (injection) process

Prototyping Support

Whether you want 2 parts or 500 parts, Cord Industries can help you with your unique rapid prototyping needs to include but not limited to:

• Stereolithography (SLA) - This option is considered the basic go-to for rapid prototyping in modern industry. One of our partners will provide you a functional 3D model from a CAD file that you can use for the first review of your design concept.

• CNC Machining - This may be an option if you’re looking to fabricate an object from a specific material.

• Low-cost Injection Molds – Usually constructed of aluminum (or in some cases 3d printed) this is the most modern-developed prototyping approach available today. It’s typically used for critical applications when other options are too limited, or when you have an urgent need of parts.

Cord Industries strives to meet your exact specifications for part design and prototyping the first time every time, and we realize that improving the quality of your parts is a key component to your business success.

We are always open to helping improve your products through technical development.